Alaabta

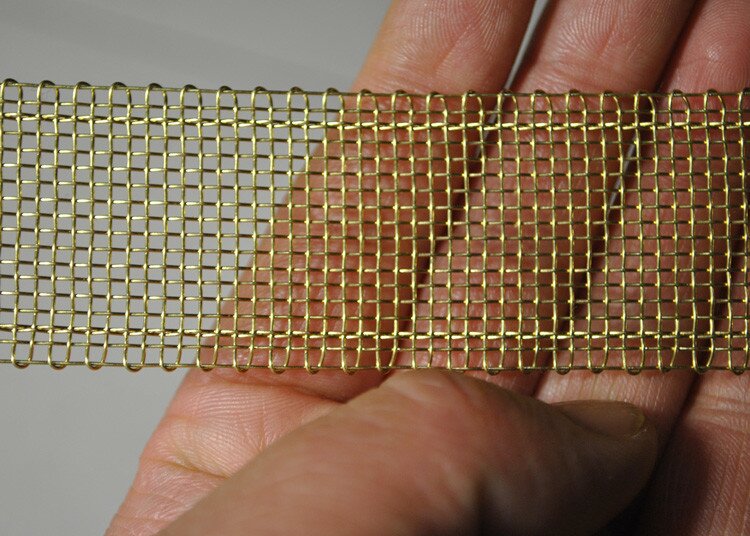

Iibiyaha Mesh Wire Copper World

Macluumaadka aasaasiga ah

Sababo la xiriira hantida wanaagsan ee naxaasta ah, Difaaca Faragelinta Soo noqnoqoshada Raadiyaha, Xadhkaha Goynta iyo Qaybaha Qabashada Iftiinka waxay caadi ahaan ku daraan marada siliga naxaasta ah.Codsiyada mesh naxaasta ah ayaa laga yaabaa inay xaddidan yihiin sababtoo ah xooggeeda jilicsanaanta oo hooseeya, caabbinta liidata ee xoqidda iyo asiidhka caadiga ah.

Halabuurka kiimikada ee mesh silig naxaas ah waa 99.9% naxaas, waa walxo jilicsan oo jilicsan.Mesh silig naxaas ah ayaa lagu heli karaa tirooyin kala duwan oo mesh ah si loo soo saaro cabbirro furan oo gaar ah si loo buuxiyo shuruudaha isticmaalayaasha warshadaha.

Warshadaha caanka ah iyo codsiyada Mesh Wire Brass

- Kaydinta tamarta

- Kuleyliyeyaasha korontada

- Uumiga xakamaynta cayayaanka

- Hoyga xeeladaysan & weelasha qaabaysan

- Robotics & Automation Power

- Gamma irradiators

- Kobcinta caafimaadka, jirka iyo maskaxda

- Barnaamijyada barnaamijka hawada sare (NASA)

- Bir-tumod & buug-xidhid

- Sifeynta hawada & dareeraha iyo kala soocida

Codsiga Mesh Wire Copper

Mesh silig naxaas ah waa ductile, malleable oo leh kulaylka iyo korantada sare.Sifooyinkan gaarka ah dartood, waxaa badanaa loo isticmaalaa sida gaashaanka RFI, gudaha Faraday Cages, saqafka saqafka iyo codsiyo koronto ku salaysan oo aan tiro lahayn.Shaki la'aan, mesh silig naxaas ah ayaa muhiim u ah warshadaha, sidaas oo kale, waxaa loo isticmaalaa codsiyada warshadaha guud.La yaab ma leh, mesh naxaasta ah ayaa inta badan u ah bartamaha horumarka tignoolajiyada ee dhinacyo kala duwan.

Midabka gaarka ah ee mesh mesh naxaasta ayaa ka dhigaya doorasho aad caan u ah noocyo badan oo isticmaalayaasha ah, oo ay ku jiraan naqshadeeyayaasha, farshaxanada, naqshadeeyayaasha iyo mulkiilayaasha guryaha.Milkiilayaasha guryuhu iyo naqshadeeyayaasha waxay doortaan mesh-ka-xidhka naxaasta ah ee mashaariicda la deggan yahay oo ay ku jiraan waardiyayaasha, muraayadaha jilicsan, shaashadda cayayaanka, iyo shaashadda dabka.Farshaxan-yaqaannada, shaqaalaha alwaaxyada, farsamayaqaannada biraha ah iyo naqshadeeyayaasha ayaa sidoo kale u arka mesh naxaasta inuu yahay ikhtiyaar aad u wanaagsan sababtoo ah midabkiisa cambar-cas ee cajiibka ah iyo soo jiidashada ballaaran ee ay u leedahay daawadayaasha ballaaran.

Halkee lagu isticmaali karaa mesh-maxaasta ah?

- RFI/EMI/RF Gaashaanka

- Ammaanka macluumaadka elegtarooniga ah

- Faraday Cages

- Koronto dhalin

- Shaashada cayayaanka

- Sahminta hawada sare iyo cilmi baarista

- Shaashada Dabka

- Ammaanka elektaroonigga ah

Mesh silig naxaas ah

Alloys naxaas - Halabuurka kiimikada caadiga ah

| 230 Naxaas Cas | 85% Copper 15% Zinc |

| 240 Naxaas hooseeya | 80% Copper 20% Zinc |

| 260 Naxaas Sare | 70% Copper 30% Zinc |

| 270 naxaas huruud ah | 65% Copper 35% Zinc |

| 280 Muntz Birta | 60% Copper 40% Zinc |

Naxaasta jaalaha ah waa daawaha ugu caansan ee naxaasta ah ee muraayadaha marada siliga.Naxaasta (sida caadiga ah 80% naxaas, 20% zinc) waxay leedahay iska caabin aad u wanaagsan oo naxaas ah, iska caabbinta daxalka oo ka wanaagsan iyo korantada hoose marka loo eego naxaasta.Hantida jilicsan ee mesh silig naxaas ah ayaa ka sarreeya kuwa naxaasta ah oo leh wax allabari ahaan qaab ahaan.Naxaasta waxay badiyaa ilaalin doontaa dhammayskeeda dhalaalaya waqti ka dib, kuma madoobaato da'da sida naxaasta.

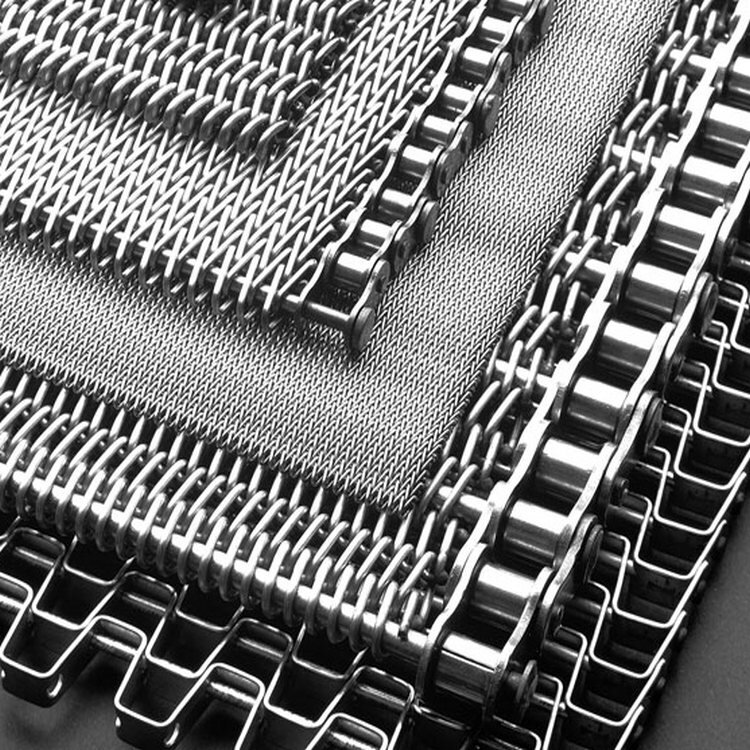

Mesh silig Bronze ah

Phosphor Bronze, Cu 94 %, Sn 4.75%, P .25%

Shabakadda siliga Fosfooraska ee naxaasta ah waxay ka samaysan tahay Copper, Tin iyo Fosfooraska (Cu: 94%, Sn: 4.75%, iyo P: .25%).Shabakadda silig bronze ee Phosphor, sida loo yaqaan, waxay soo bandhigtaa sifooyin jireed iyo kuwa ka-hortagga daxalka oo waxyar ka sarreeya kuwa naxaasta iyo aluminiumka zinc.Shabakadda silig naxaasta ah ee fosfooraska ayaa caadi ahaan laga helaa meshes-ka aadka u fiican (100 x 100 Mesh iyo finner).Qalabkani wuxuu leeyahay xoog weyn, adkeysi iyo ductility.Waxa kale oo ay u adkaysataa walxaha daxalka caadiga ah.

Faahfaahinta qayb ka mid ah mesh silig naxaas ah

| Mesh/In | Wire Dia. (In) | Furitaanka | Aagga Furan (%) | Nooca Tolmada | Ballaca |

| 2 | 0.063 | 0.437 | 76 | PSW | 36" |

| 4 | 0.047 | 0.203 | 65 | PSW | 40" |

| 8 | 0.028 | 0.097 | 60 | PSW | 36" |

| 16 | 0.018 | 0.044 | 50 | PSW | 36" |

| 18 x 14 | 0.011 | 0.044 X 0.06 | 67 | PW | 48" |

| 18 x 14 | 0.011 | 0.044 X 0.06 | 67 | PW | 60" |

| 20 | 0.016 | 0.034 | 46 | PSW | 36" |

| 30 | 0.012 | 0.021 | 40 | PSW | 40" |

| 40 | 0.01 | 0.015 | 36 | PSW | 36" |

| 50 | 0.009 | 0.011 | 30 | PSW | 36" |

| 100 | 0.0045 | 0.0055 | 30 | PSW | 40" |

| 150 | 0.0026 | 0.004 | 37 | PSW | 36" |

| 200 | 0.0021 | 0.0029 | 33 | PSW | 36" |

| 250 | 0.0016 | 0.0024 | 36 | PSW | 40" |

| 325 | 0.0014 | 0.0016 | 29 | TSW | 36" |

| 400 | 0.00098 | 0.00152 | 36 | PSW | 39.4" |

| Nooca | Isku-xidhka Xadhkaha Cas ee Copper | Mesh silig naxaas ah | Fosfoor | Copper qasacadaysan Mesh silig |

| Qalabka | 99.99% silig naxaas saafi ah | H65 silig (65%Cu-35%Zn) | Tin silig naxaas ah | Silig naxaas ah oo qasacadaysan |

| Tirada Mesh | 2-300 mesh | 2-250 mesh | 2-500 mesh | 2-100 mesh |

| Nooca Tolmada | Weave Plain/Twill and Dutch Weave | |||

| Cabirka Guud | Ballaca 0.03m-3m;Dhererka 30m / duub, sidoo kale waa la beddeli karaa. | |||

| Tilmaamaha Guud | Nonmagnetic, ductility wanaagsan, Xiro iska caabin, | |||

| Tilmaamaha Gaarka ah | Dahaarka codka | Ilaali dhammayntiisa dhalaalaya wakhti ka dib | Xoog weyn, adkeysi iyo ductility | Iska caabin heerkul sare ah, gabowga lidka ku ah, iyo nolosha adeeg dheer |

| Codsiyada caadiga ah | EMI/RF gaashaandhigga | Codso wargeyska/ Qorista/daabacaadda chinaware; Shaashada sigaarka; | Codso | Shaandheeyaha mishiinka baabuurta, |